Elektro-Thermit GmbH & Co. KG – A Goldschmidt Company

Booth number: F154B

www.goldschmidt.com/en

About us

Together with you, Goldschmidt masters the challenges of modern, railbound mobility – for safe, sustainable and long-lasting railways of premium quality.

As with Thermit®, Goldschmidt is also a pioneer in maintenance, inspection and digitalization and continues to improve processes and extend the lifecycle of railway infrastructure. Goldschmidt benefits from its global expertise and cross-disciplinary thinking to create tailor-made local solutions for you. The global presence of Goldschmidt gives you access to its whole portfolio – with one goal: to lead your railway infrastructure into the future.

You can find all information about the Goldschmidt Group at: www.goldschmidt.com

Address

Chemiestr. 24

06132 Halle (Saale)

Germany

E-mail: et@goldschmidt.com

Phone: +49 345 7795600

Internet: www.goldschmidt.com

Contact person:

Alexander Müller

Sales / Export

E-mail: alexander.mueller@goldschmidt.com

Phone: +49 172 2594140

Products & Services

Elektro-Thermit is a part of the Goldschmidt Group and a global leading process provider for Thermit® welding and develops, produces and supplies all components that are required for the Thermit® welding process. Tools and machines with a digital interface complete the portfolio and enables further analysis and visualizations. The portfolio includes:

Consumables, equipment and machines for Thermit® welding processes

+ S battery machine portfolio powered by EGO

Track measuring technology

Insulated rail joints MT, ETW1

Goldschmidt Inspection Germany is a part of the Goldschmidt Group and offers a range of sophisticated methods, devices and services for surface and volume testing on installed rails. This includes:

Device checks for the entire spectrum of eddy current and ultrasonic testing devices as well as mobile and stationary magnetization devices

Inspection services of products of the metal producing and processing industry

Support in the development of customized test concepts and standards

The whole portfolio: www.goldschmidt.com

Original Thermit® welding process

Process for welding rails – for laying rails and for track expansions, maintenance and complete renewal

Use in long-distance, regional and local transport and on industrial railways

Welding of almost all rail profiles and rail grades

Test for new application areas, e.g. sealing of oil wells

Numerous certifications according to international standards underline our competence.

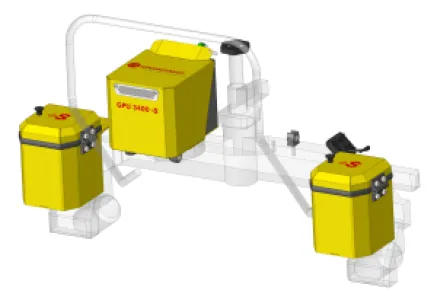

Retrofit Kit GPU 3400 +S

The high-performance and robust drive unit GPU 3400 +S was specially developed for rail grinding machines. Existing machines with a combustion engine can be easily retrofitted with the battery-driven system. The battery drive is particularly suitable for use in tunnels and inner-city areas.

Compatible with many common rail grinding machines

Preferred use of the converted grinder in tunnels and urban environments

Increased user-friendliness due to reduced hand-arm vibration

Infinitely adjustable power

Minimised noise emissions

Elimination of exhaust emissions

Up to 60 minutes of runtime per battery charge

Predictive work planning by monitoring the battery charge status

Commercially available lithium-ion batteries

Charging time of just 75 minutes for a 12 Ah battery

Multiple charging options available, including mobile charging

Trackscan Use-B

The ultrasonic rail inspection system Trackscan Use-B detects, among other things, deep head checks, squats and corrosion at the rail foot. The result data can also be imported into the customer’s own infrastructure data.

Detect and evaluate volume defects seamlessly

2D visualisation of "Glassy rails“ in A-scan or B-scan view

Filter function against influences

Complete storage of raw data

Low maintenance costs due to modular design

Modern lightweight construction using fibre composites

Inspection possible in forward and reverse operation

Suitable for left-handed and right-handed users