VEM GmbH

Booth number: G174D

www.vem-group.com

About us

VEM has been developing and producing rail traction machines for more than 130 years. This is a treasure trove of experience enabling us to meet the demanding needs of the international rail vehicle industry for high performance drive solutions. That includes highly efficient asynchronous traction motors for electrical or diesel-electrical locomotives, multiple units, trams and working vehicles as well as main and auxiliary operating generators and their regulating systems. VEM also offers traction motors for hybrid-, EV- and trolley buses for environmentally friendly local public transport.

- Traction motors up to 1,800 kW

- Traction generators up to 5,000 kVA

- Auxiliary generators up to 1,000 kVA

Address

Pirnaer Landstr. 176

01257 Dresden

Germany

E-mail: vemgmbh@vem-group.com

Phone: +49 351 208-0

Internet: www.vem-group.com

Contact person:

Axel Neunert

Sales Manager Public Transportation & Rolling Stock

E-mail: axel.neunert@vem-group.com

Phone: +49 351 208-3246

Hans-Georg Becker

Executive Sales Manager Public Transportation & Rolling Stock

E-mail: hans-georg.becker@vem-group.com

Phone: +49 351 208-1211

Products & Services

- Traction motors up to 1,800 kW

- Traction generators up to 5,000 kVA

- Auxiliary generators up to 1,000 kVA

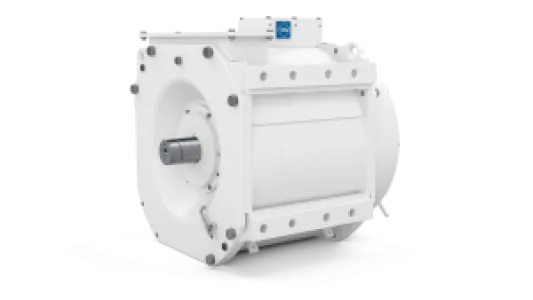

Traction motors for Public Transportation and Rolling Stock

Our three-phase asynchronous motors impress with their compact design and high performance – ideal for use in rail vehicles and buses. Their high efficiency minimizes energy losses, extends the service life of the vehicles, and reduces operating costs. Furthermore, their quiet operation ensures increased ride comfort for both passengers and drivers.

Technical parameters

Power range: 45 - 1,800 kW

Voltage range: 400 V - 3,000 V

Protection class: IP 21 - IP 66

Number of poles: 4 - 8

Insulation system: VPI-200

Cooling system

water-cooled

forced ventilation

self-ventilated (surface-cooled, open circulation)

Technical Design

Single bearing

Double bearing

Longitudinal arrangement (dual engine, axle drive, wheel drive) Transverse arrangement (axle drive)

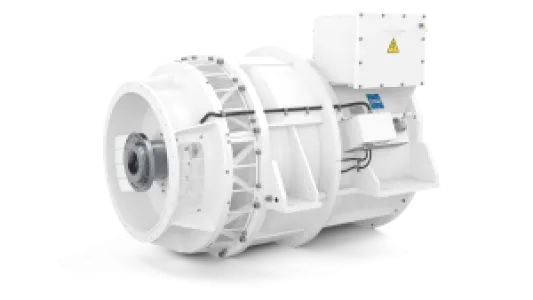

Generators for Public Transportation and Rolling Stock

In addition to electrically excited synchronous generators, we also develop and supply asynchronous generators and permanent-magnet synchronous generators. They serve as the central power source for traction and on-board power supplies, are directly coupled to the diesel engine, and reliably supply both the traction motors and on-board equipment with energy.

Our broad portfolio covers power ranges from 30 to 5,000 kVA, thus meeting virtually every requirement. It includes both single- and dual-bearing generators, which are reliably in use in hundreds of vehicles worldwide under a wide variety of climatic conditions. Traction generators for mining vehicles are also part of our product range.

Technical parameters

Power range: 30 - 5,000 kW

Voltage range: 400 V - 3,000 V

Protection class: IP 21 - IP 66

Number of poles: 4 - 8

Insulation system: VPI-180

Cooling system

water-cooled

forced ventilation

self-ventilated

Technical Design

Easy storage

Double storage

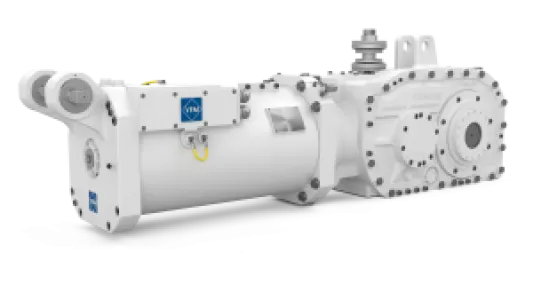

Motor-gearbox unit for Public Transportation and Rolling Stock

Thanks to close cooperation with leading rail gearbox and coupling manufacturers, VEM offers complete drive trains for light rail vehicles, multiple units, and locomotives – consisting of motor, coupling, and gearbox. Our many years of experience enable the development of customized motor-gearbox units that not only meet the highest performance requirements but also optimally accommodate strict specifications regarding weight and installation space.

Technical Design

Single bearing + transmission

Double bearing + transmission

Longitudinal arrangement (dual engine, axle drive, wheel drive) + transmission

Transverse arrangement (axle drive) + transmission

Cooling system

Water-cooled

Forced ventilation

Self-ventilated (surface-cooled, open circulation)

Motors for railway drives for Public Transportation and Rolling Stock

Motors for railway drives, especially fan motors, must meet specific requirements in order to be used in rail vehicles. These engines are manufactured in a special railway design to withstand the extreme conditions that prevail in railway operations. Challenges include shock and vibration caused by rail operation, inverter control and the ability to handle high temperatures. These special requirements ensure that the engines in rail vehicles operate reliably and efficiently, even under the most demanding operating conditions.

Features

Motors for railway drives, especially fan motors, are characterized by their special railway design, which is optimized for use in rail vehicles. They are robustly built to withstand shock and vibration caused by operating on rails. In addition, they are designed to be controlled via inverters, which enables precise control of the motor speed. These engines are also capable of handling high temperatures, which are common in rail operations. Their design ensures high reliability and durability under extreme conditions, making them ideal for use in rail vehicles.

Applications

Train drive motors are used in a variety of rail vehicles, including trains, trams and subways. They are mainly used as fan motors to ensure cooling of electrical and mechanical components, increasing the efficiency and service life of vehicles. These engines are also integrated into drive trains, where they propel the vehicles. Thanks to their robust construction and their ability to work in extreme conditions, they are essential for the reliable and efficient operation of rail vehicles in various climatic and operational environments.

Our range of services

Compact drives for the railway sector are mainly used to control controlled fans in trains to ensure optimal air conditioning of the passenger compartments and efficient cooling of the traction motors and transformers. These drives must meet high mechanical and electrical requirements and withstand extreme climatic conditions as well as vibration and shock loads. According to DIN EN 61373, they must withstand impacts of 5 g and temperature ranges from -25 to +50 °C without losing performance. They also have to start at +70 °C and deliver full power for 10 minutes. Temperature changes of up to 3 K/s when entering and exiting tunnels represent additional requirements. The motors and frequency converters must remain powerful across the entire frequency range and must be manufactured according to special railway standards and regularly maintained to ensure a service life of 30 years.