ASC GmbH

Booth number: F155D

www.asc-sensors.de

About us

Smart rail

High-precision sensors from ASC ensure safe and comfortable train operation

Accurate. Stable. Certifies

From Germany to the whole world, we deliver our high-quality sensors which meet also EN 50155

Analog - Digital - Smart

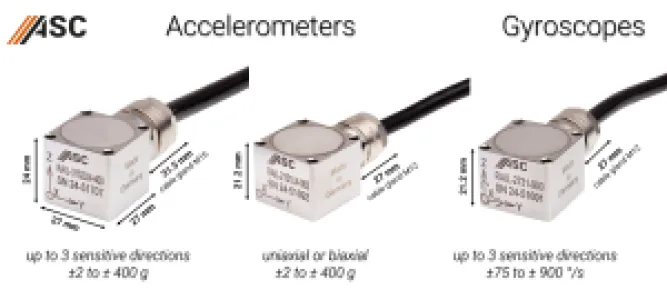

acceleration sensors (capacitive, piezoresistive, IEPE)

angular rate sensors

inclination sensors

inertial measurement units (IMUs)

Modern rail traffic would be inconceivable without inertial sensors. ASC sensors detect the position of trains, monitor the condition of the tracks and enable maximum ride comfort through use in the following applications, for example:

Bogie strength (EN13749)

Running dynamics tests ( EN14363)

Ride comfort measurements (EN12299)

Track position data acquisition (EN13848)

Bridging Navigation

Infrastructure monitoring (e.g, track, bridges, tunnels)

Predictive Maintenance - Vehicle and Infrastructure

In the development and operation of trains, inertial sensors perform numerous important tasks. One of them is the highly accurate measurement of oscillations and vibrations on vehicles, track systems and bridges. The data thus obtained forms the basis for safe, comfortable rail traffic.

Fatigue testing under the harshest conditions (EN 14363 and EN 13749)

ASC's capacitive acceleration sensors contribute to the operational safety of trains, among other things. Among other things, they are used to measure running dynamics (according to EN 14363) and bogie strength (according to EN 13749) under real conditions. The sensors are extremely robust against the effects of weather, can even withstand impacts with an intensity of up to 6,000 g and operate in a temperature range between -40 °C and +125 °C.

Damage to tracks is detected at an early stage (EN 13848)

ASC inertial sensors are also indispensable for monitoring the condition of the track network in accordance with EN 13848. They record, for example, vertical acceleration at the wheelset bearings and acceleration inside the car bodies. Based on the data obtained, irregularities in the longitudinal height of the track body can be detected

Running Dynamics (EN 14363) and Bogie Strength (EN 13749)

New rail vehicles are tested to rigorous screenings in accordance with EN14363 (running dynamics) and EN13749 (bogie strength) standards. During these tests normal train operation in every conceivable operating situation are simulated. In these intense test runs, high-precision ASC capacitive acceleration sensors are used, like the ASC OS-series or ASC RAIL-series.

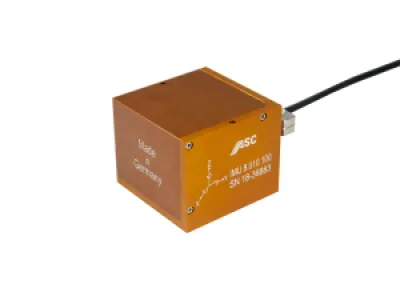

Bridging navigation for disturbed GNSS signals

Determine the orientation with high precision even if the GNSS signal is temporarily unavailable? In this case, bridging navigation using inertial sensors is required. The ASC IMU 8 makes it possible by permanently and precisely detecting the position of motion and objects in rail vehicles. The ASC IMU 8 features excellent bias stability of the integrated acceleration sensors (3 to 45 μg). Furthermore, the angular rate sensors (Tactical Grade) feature a minimum angular random walk of <0.01 °/√h and a bias stability of <0.1 °/h. The error regarding velocity, position and orientation calculation is thus very low, resulting in a deviation of only 20 cm after 60 seconds when using the ASC IMU 8.

Address

Ledererstr. 10

85276 Pfaffenhofen

Germany

E-mail: r.bay@asc-sensors.de

Phone: +49 8441 7865470

Internet: www.asc-sensors.de

Albasanz 16

Grupo Alava

28037 Madrid

Spain

E-mail: alava@grupoalava.com

Phone: +34 91 5679700

Internet: www.grupoalava.com

Contact person:

Products & Services

ASC Inertial Sensor Technology

High-accuracy ASC sensors ensure safe and comfortable train operation

Without inertial sensors, modern rail transport would be inconceivable. They detect the position of trains, monitor the state of the tracks, and ensure optimal travel comfort. The smart sensor systems ASC AiSys® enable real-time monitoring of the assets and early detection of damages, so that infrastructure operators can plan their maintenance activities even more efficiently in the future.

Inertial sensors perform numerous important tasks in the development and operation of trains. One of them is high-precision measurement of oscillations and vibrations on rolling stock, tracks, and bridges. The data obtained from these measurements form the basis for safe, comfortable rail transport. Engineers can draw valuable information from them for train design and infrastructure maintenance. Sensors also ensure that the train dispatchers at the Deutsche Bahn railway control centers always know the exact location of any given train. Satellite navigation alone is not enough, because the signals are susceptible to interference.

ASC is specialized in measurement technology and manufactures a wide range of highly accurate accelerometers and gyroscopes, as well as Inertial Measurement Units (IMU) for rail transport testing and monitoring or bogie monitoring of high speed trains. The sensors collect data in a wide variety of applications – not only in rolling stock, but also on tracks or bridges.

ASC 4411LN accelerometer used for Passenger ride comfort (EN 12299)

Analyzing the effects of train motions on passenger ride comfort is necessary because human perception of mechanical vibrations varies greatly, depending on their direction, frequency and amplitude. Passenger inconveniences, however, occur primarily below 10 Hz, so that precise measurements of minimal linear motions, low-frequency vibrations and impacts are essential to optimizing ride comfort.

ASC OS-series used for characterization of track geometry (EN 13848)

ASC accelerometers and gyroscopes are integrated in tailormade measurement systems to enable infrastructure monitoring from regular in-service trains. Based on accurate results deviation in longitudinal height, dynamic direction or distortion or ftracks are calculated.

ASC EQ series used for Infrastructure monitoring

Continuous and ad-hoc measurements of the structural health of railway assets like track bed, sleepers, switches or tunnels are crucial for improved availability and safety. The analog and digital accelerometers of the ASC EQ series feature extremely high resolutions. With their ability to register amplitudes of a millionth of the earth's gravitational acceleration, the sensors are often used in seismological monitoring applications.

ASC 4421MF used for dynamic interaction between pantograph and overhead contact line (EN 50317)

Measurements of the contact force and dynamic response are performed in challenging environmental conditions with electromagnetic interferences present, as the sensore are installed very close to the catenary. The uniaxial accelerometers ASC 4421MF are ideally suited due to their flat design and a low mass, which is of special importance to avoid aerodynamic interferences.

ASC RAIL-3152 used for running characteristics of railway vehicles (EN 14363)

For the safe and economical operation of railway systems, running behavior tests are essential. The goal is to quantify vehicles under known, representative operating and infrastructure conditions. Using various inertial ASC sensors at the axle box, bogie frame and diverse positions in the vehicle body, significant accelerations are accurately measured.

ASC 4411LN used for passenger ride comfort (EN 12299)

Analyzing the effects of train motions on passenger ride comfort is necessary because human perception of mechanical vibrations varies greatly, depending on their direction, frequency and amplitude. Passenger inconveniences, however, occur primarily below 10 Hz, so that precise measurements of minimal linear motions, low-frequency vibrations and impacts are essential to optimizing ride comfort.