Lenord, Bauer & Co. GmbH

Booth number: G176D

www.lenord.com

About us

Our durable sensors have stood the test in rail vehicles for decades. Lenord+Bauer offers the right solutions for all conceivable requirements and applications in relation to the bogie. Our plug-and-play sensor systems reliably acquire rotational speed, temperature, acceleration or mileage.

The sensors used are directly exposed to the elements as well as rocks and dust. That’s why the electronic components of our products are protected from extreme climate conditions, humidity, shock, impact and vibration by special manufacturing methods.

We always create individual solutions in close cooperation with our customers.

Talk to us!

Application examples:

Traction and roll protection

Wheel slide protection

Bogie monitoring

Gearbox monitoring

Automatic Train Protection

Address

Dohlenstr. 32

46145 Oberhausen

Germany

E-mail: info@lenord.de

Phone: +49 208 9963-0

Internet: www.lenord.com

Contact person:

Ulrich Rink

Chief Sales Officer/ Managing Director International Sales

E-mail: urink@lenord.de

Torsten Kassing

Key Account Manager - Rail Systems

E-mail: tkassing@lenord.de

Phone: +49 208 9963-0

Jan Niklas Schwarte

Product Manager Sensors

E-mail: jschwarte@lenord.de

Phone: +49 208 9963-0

Products & Services

Vehicle sensors for railroad applications

Speed sensors

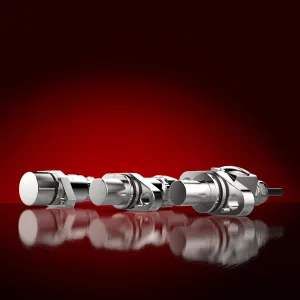

Threaded sensors

Axle and rotary encoders

Temperature sensors

Rotor position encoders

Multisystem sensors

Condition monitoring sensors

Speed sensors: For heavy-duty applications

Acquisition of rotational speed and speed according to needs

Shock and vibration resistant due to encapsulation of the electronics

Degree of protection IP 68: Dust and water-proof according to DIN EN 60529

Reliable at temperatures from -40 °C to +120 °C

Electromagnetic compatibility according to DIN EN 50121-3-2

Simple mounting: Extremely compact design with standard flanges

Ready for immediate use as a plug-and-play system

Our speed sensors acquire movements from 0 Hz just as reliably as fast rotations up to 25 kHz. As they operate without contact, they are entirely maintenance and wear free.

Whether they are part of the wider portfolio or are customer-specific - Lenord+Bauer speed sensors are durable, high-quality and tested to comply with standards in every respect.

Tailor-made for your application

We adapt our sensors to your needs. If the mounting position of the sensor and target wheel requires a specific position of the active elements in the sensor tip, we position the sensor elements according to your requirements. We also design special functions and special flanges for our customers. Tell us your wishes and we will integrate, for example, a pulse divider or a self-test in the electronics.

Axle and rotary encoders: Tailored for extreme conditions

For mounting on internally or externally mounted bogies

Various flange forms for every vehicle type

Max. 8 channels

Max. 3 different pulse numbers

Cold Movement Detection function can be integrated (ETCS level 3)

Today, precise measured values are required for real-time control. Rotary encoders with their own bearings and a wide variety of housing designs are used in this instance. A typical feature of these measuring systems is that the scanning unit and the target wheel are integrated in a single housing. Both components are precisely matched to each other.

With pulse rates of up to 10,000 increments per revolution, the encoders cover all measurement requirements in the vehicle and have proven themselves in railroad rolling stock for decades.

Proven incremental rotary encoders

Our proven magnetic incremental encoders acquire the change in angle on a rotating shaft. The integrated sensors scan the built-in target wheel in contactless mode. The magnetic sensor system supplies 1-Vpp differential signals, HTL or TTL signals. The direction of rotation, the distance traveled and the speed of the rotating shaft can be determined from the signals generated, as an axle or motor encoder.

One axle encoder – many output signals

We offer special multi-channel axle encoders for wheel slide protection, train protection and secondary applications on the bogie. They provide different signals for several controllers and thus utilize their full potential.

The sensors emit independent square-wave signals on up to eight channels. The push-pull electronics generate up to three different pulse numbers. Output is either in voltage or current levels. The channels can be configured and output either individually or in groups with fixed phase relationship. This allows the characteristics of the output signals to be matched accurately to the control units. This solution is individually tailored to the application.

Measuring systems for high loads

Extreme shaft loads frequently occur in rail transport. We offer precision encoders with a special coupling for this special load. The integrated and flexible hollow shaft coupling with a diameter of 20 mm enables attachment to motors with high axial and radial shaft movements. Alternatively, a rotary encoder series with a 16 mm solid shaft is available. Up to 5 independent and fully encapsulated sensor modules can be placed in a stainless steel housing. We adapt each module individually to your application and the control system. The system thus offers a wide range of applications.

Withstanding extreme weather conditions

All rotary encoders provide accurate measured values even under changing temperatures, humidity, strong vibrations and condensation. Additional protective measures can be selected for special environmental influences, such as protective coatings or condensed water outlets. Talk to us.

CombiCODER: Space saving acquisition of vibrations and temperatures

Six sensors in one housing

Acquisition of rotational speed, vibration, and temperature

Compact design based on a modular system

50% less installation effort

If the installation space on the undercarriage is limited, our CombiCODER combines several sensor types in a single housing. For example, they simultaneously measure rotational speed, temperature and vibrations.

Alternatively, we combine different sensors individually according to your specifications and adapt the design if necessary. Your advantage: Instead of mounting three to four sensors, you only have to mount and test one sensor. This reduces the effort required for assembly and preventive maintenance significantly.

Upon request, we manufacture special flanges or connect, for example, the temperature sensor to a speed sensor using a cable harness. This greatly simplifies cabling.

Temperature acquisition

The temperature of motors and bearings can indicate inefficient or even critical conditions. Our compact platinum resistance thermometers record any changes and warn of any unwanted heat build-up on the undercarriage. The compact temperature sensors according to DIN EN 60751 are available with stainless steel tubes and brass flanges. For optimal measurement, we adapt the length of the measuring tube to your application.

Vibration and shock acquisition

Mechanical influences such as flat spots in the wheel rim or imperfections in the rail place the undercarriage under stress. To detect these stresses at an early stage, we use MEMS devices, among other devices. Their measured values provide information about shocks and vibrations suffered.

Threaded sensors: Space saving sensor with standard thread types

The multi-talent adapts to all retrofit projects

Multi-channel capability

Thick-walled stainless steel housing

Safe detection slow motion (0 Hz)

Complies with the requirements of DIN EN 50155 and DIN EN 45545-2

Also in customer-specific thread types and lengths

Special types also in small quantities

To ensure that modern train control systems receive reliable rotational speed signals, vehicle operators have to regularly replace passive sensors with active ones. Our screw-in threaded sensors are used to upgrade rail vehicles to the state of the art to enable continued operation.

Space-saving assembly variant

In addition to tried-and-tested speed sensors with flange housing, threaded sensors with one or alternatively two channels are another assembly variant for threaded or through holes. These spacesaving sensors can be easily integrated into existing designs without any mechanical adjustments thanks to standard thread types and nominal lengths as well as individual cable fabrication.

They acquire the rotational speed and direction of rotation directly at the motor or gearbox and detect even the smallest movements of the drive with a measuring range of 0 Hz to 20 kHz.

Robust, high-resolution sensors were developed for use in the harshest ambient conditions. They are suitable, for example, for traction control and train protection. The maintenance- and wear-free magnetic measuring system in the thick-walled stainless steel housing withstands both shocks and vibrations. Certification in accordance with DNV GL, SIL, ATEX or IECEx is possible as an option.

Multisystem sensors: Speed sensor with various signal pattern combinations

One sensor provides signals for up to four control systems

Integration of different signal patterns in the familiar flange housing

Perfectly suited for retrofits and for retrofitting additional systems

No mechanical adjustments required

Cost-efficient due to reduced cabling effort (cables, cable protection, connectors)

Electrically isolated rotational speed systems for operation on different supply voltages and control systems

Large permissible measuring distance facilitates design and assembly

High-quality diagnostic units ensure greater railroad safety. The individual applications require very different signal properties. Our multi-system sensors are the space-saving solution for users with a growing number of control devices. Up to four independent speed sensors are integrated in an industry-standard housing.

Four separate sensor units are technically feasible. If necessary, every control system has its own power supply and is electrically isolated. If need be, two channels can be generated with a fixed phase relationship. The requirements of all applications can be combined in a single housing from the traction control to the brake control.